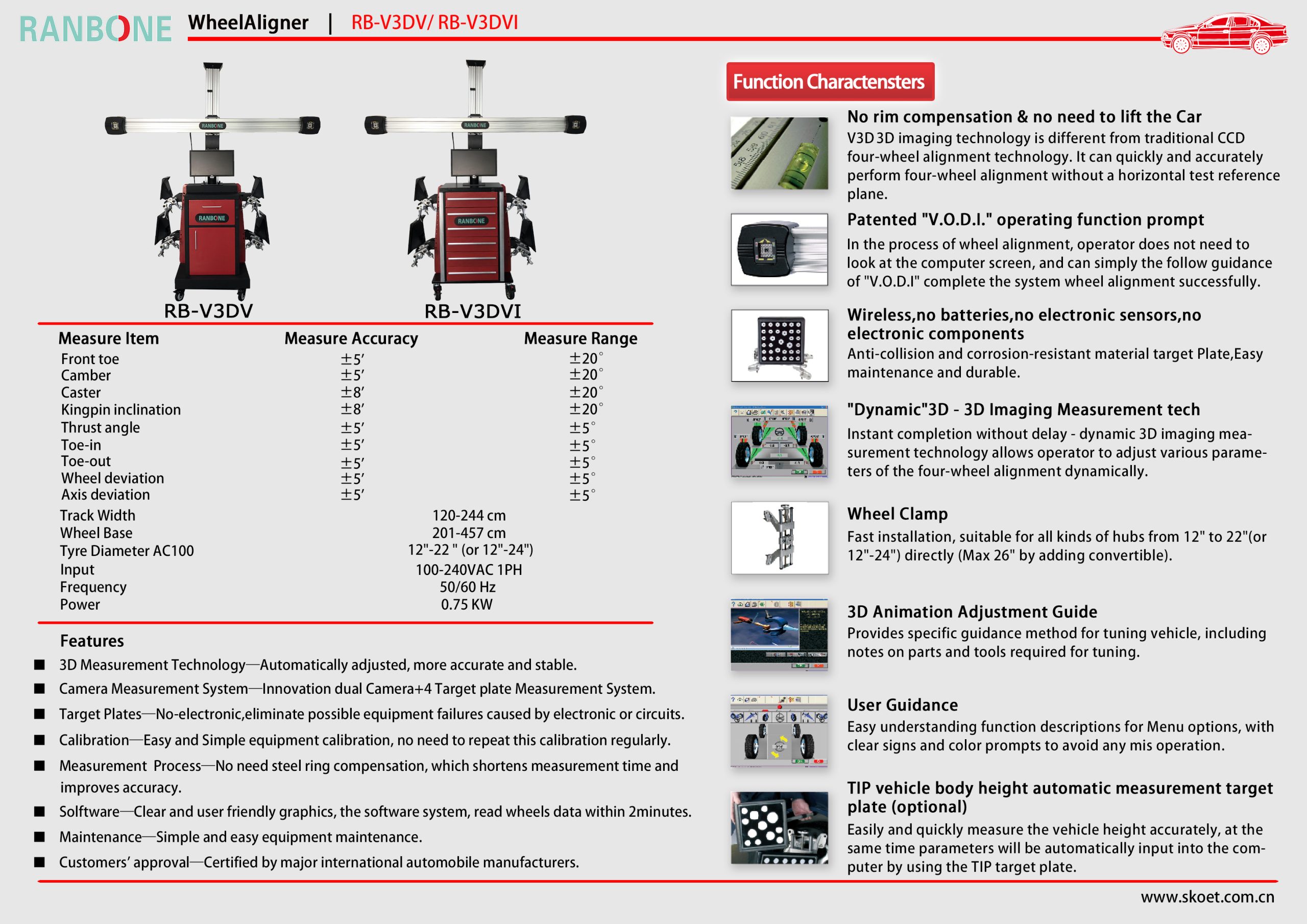

3D Measurement Technology—Automatically adjusted, more accurate and stable.

Camera Measurement System—Innovation dual Camera+4 Target plate Measurement System.

Target Plates——No-electronic, eliminate possible equipment failures caused by electronic or circuits.

Calibration—Easy and Simple equipment calibration, no need to repeat this calibration regularly.

Measurement Process—No need steel ring compensation, which shortens measurement time and improves accuracy.

Software —Clear and user friendly graphics, the software system, read wheels data within 2minutes mechanischer bulle.

Maintenance—Simple and easy equipment maintenance.

Customers’ approval—Certified by major international automobile manufacturers.

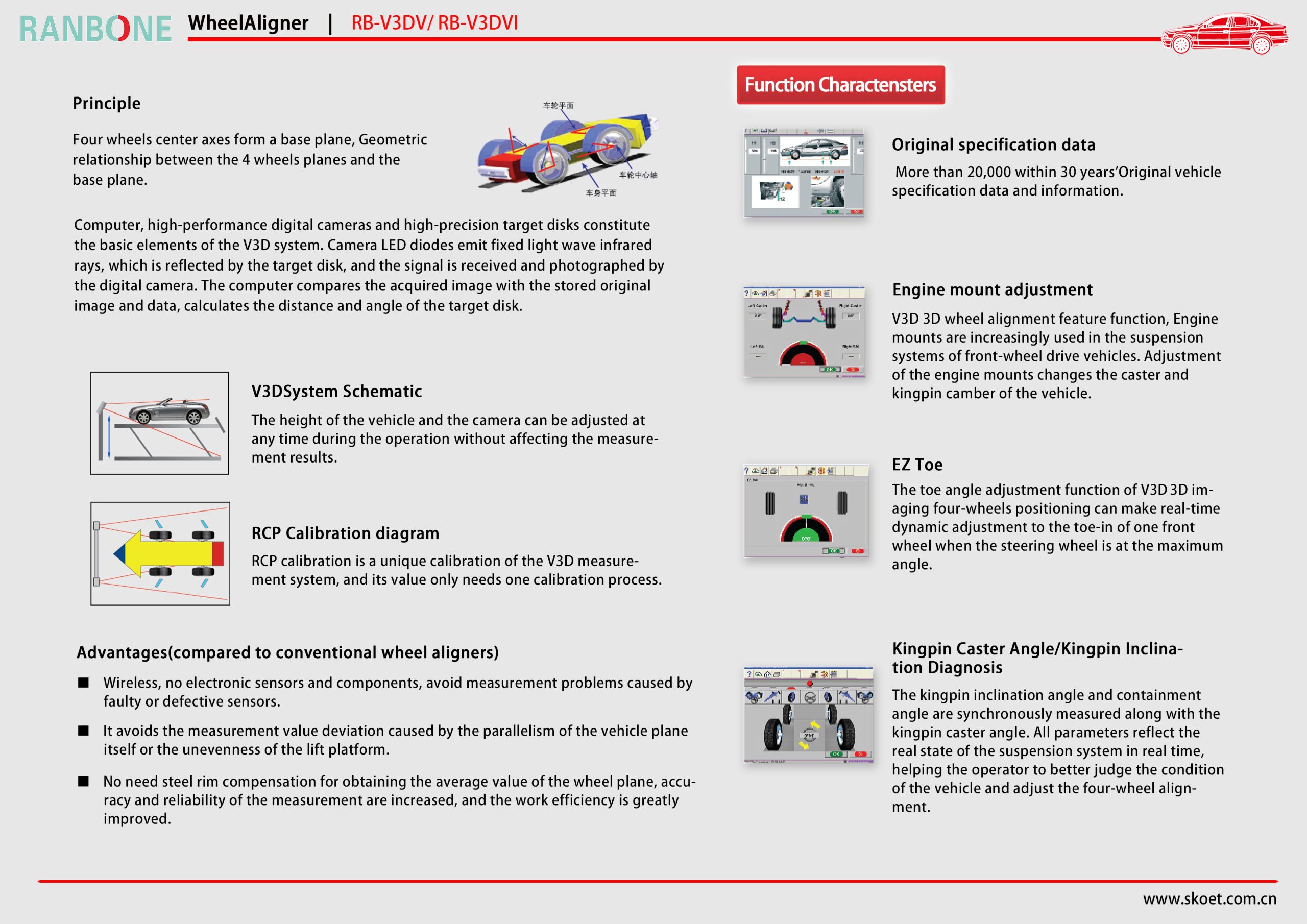

No rim compensation & no need to lift the Car V3D 3D imaging technology is different from traditional CCD four-wheel alignment technology. It can quickly and accurately perform four-wheel alignment without a horizontal test reference plane.

In the process of wheel alignment,operator does not need to look at the computer screen, and can simply the follow guidance of “V.O.D.I” complete the system wheel alignment successfully.

Anti-collision and corrosion-resistant material target Plate,Easy maintenance and durable.

Instant completion without delay-dynamic 3D imaging mea-surement technology allows operator to adjust various parame-ters of the four-wheel alignment dynamically.

Fast installation, suitable for all kinds of hubs from 12″ to 22″(or 12″-24″)directly (Max 26″ by adding convertible).

Provides specific guidance method for tuning vehicle,including notes on parts and tools required for tuning.

Easy understanding function descriptions for Menu options,with clear signs and color prompts to avoid any mis operation.

Easily and quickly measure the vehicle height accurately,at the same time parameters will be automatically input into the com-puter by using the TIP target plate.

RB-V3DVI Datasheet(cick to download) 2022-08-05